RPA Inspections & Advanced Reality Modelling

SIE has the technical resources and capability to generate highly detailed 3D reality models of structural assets, which provide an accurate and current record of their condition. Structural modelling is increasingly essential for monitoring remedial works, tracking upgrades and capturing ongoing changes. SIE utilises in-house drone pilots and a combination of UAV assets, along with the most advanced tools, to enable smarter, data-driven asset management.

Capturing the Real Picture, From Every Angle

SIE provides advanced RPA (Remotely Piloted Aircraft) inspection and reality modelling services to the mining, ports, and heavy industrial infrastructure sectors. Our team combines deep structural engineering expertise with cutting-edge drone technology and photogrammetry to deliver high-resolution visual data and accurate 3D models of assets & environments. These capabilities allow for safe, efficient, and non-intrusive inspections of hard-to-access structures, supporting both routine condition monitoring and incident investigations.

Our reality modelling services enable clients to visualise and analyse their assets in detail, facilitating informed decision-making across maintenance planning, compliance verification, and risk management. SIE has supported clients with a range of aerial inspection and modelling applications, including:

- High-resolution drone inspections of critical infrastructure such as conveyors, stackers, reclaimers, and wharf structures.

- Generation of 3D reality models for structural condition assessments.

- Integration of reality models with design models to validate structural compatibility, ensure repair components will fit and align as intended.

Accurate Models & Reliable Assessments For Your Assets

Our clients benefit from SIE’s unique combination of structural engineering knowledge and advanced aerial inspection capabilities. By leveraging RPA technology and reality modelling, we deliver:

- Rapid deployment and data capture in response to incidents or urgent inspection needs, minimising downtime and improving safety.

- Detailed visual records and 3D models that enhance understanding of asset condition and support long-term maintenance strategies.

- Non-invasive inspection methods that eliminate the need for shutdowns, scaffolding or elevated work platforms, reducing operational disruption.

- Clear, structured reporting tailored to technical, legal, or management audiences, supported by high-quality imagery and model data.

- Enhanced risk management through early detection of structural vulnerabilities and integration of inspection data into broader asset integrity programs.

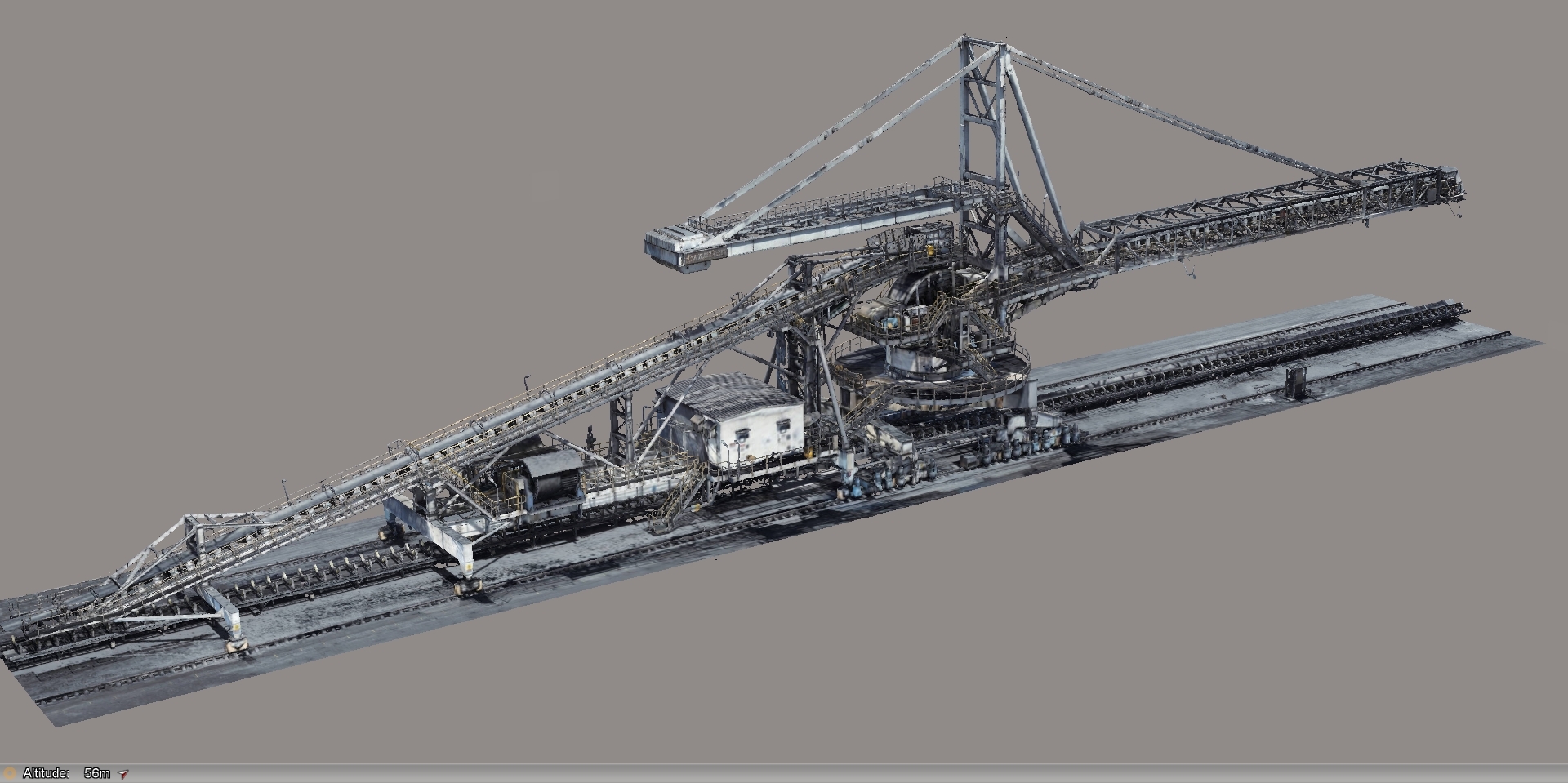

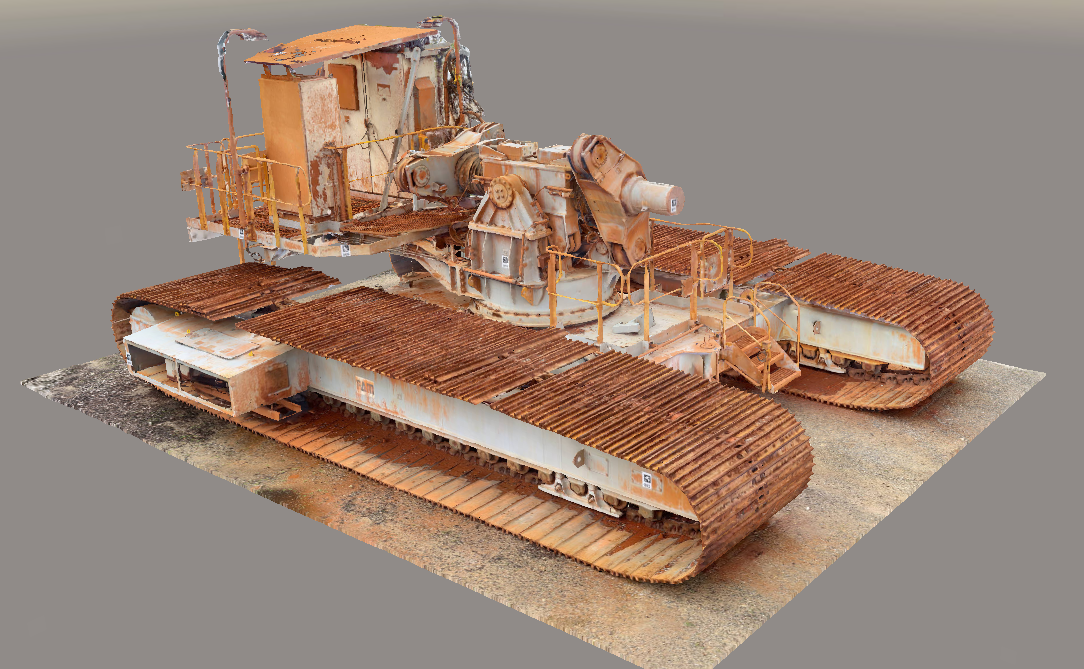

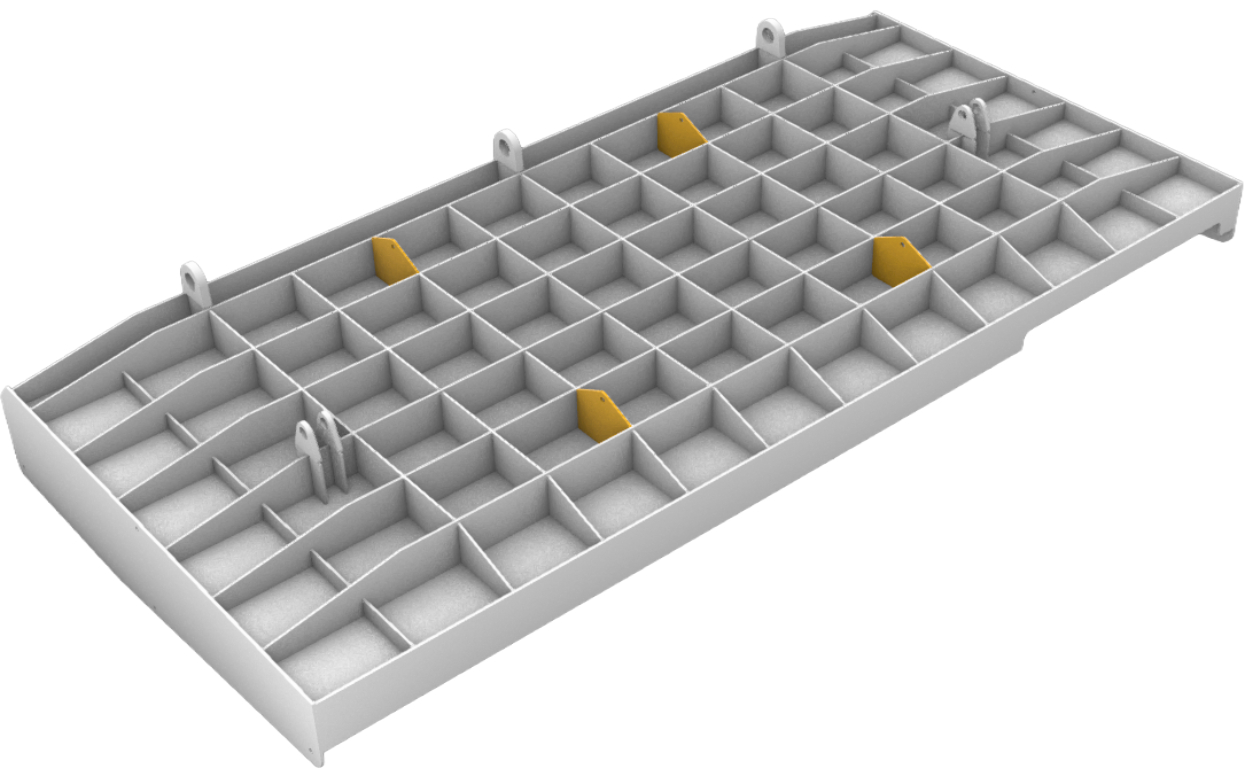

Some of our Reality Modelling Projects:

Crawler Inspection and Reality Modelling

SIE conducted a comprehensive inspection of each crawler assembly on a large spreader machine using high-resolution imaging techniques. These images were processed through photogrammetry software to produce highly detailed 3D models of each crawler, capturing the structural geometry and condition with precision.

This process supported accurate reporting of wear, deformation, and other structural indicators, while also creating a permanent digital record of the crawler assemblies. These records serve as a valuable reference for future inspections, maintenance planning, and lifecycle asset management.

Spill Tray Reverse Engineering and 3D Model Integration

SIE conducted site measurements and captured high-resolution imagery of an existing spill tray during a scheduled shutdown. Using photogrammetry, a detailed 3D model of the tray was created to accurately represent its geometry and structural features.

This model was then used to overlay and align with the newly developed design, allowing engineers to verify dimensional compatibility and ensure the new spill tray would match the existing structure prior to fabrication. This process helped confirm fit and alignment, reduced uncertainty, and supported efficient drawing production tailored to local manufacturing standards.

Shiploader Inspection and Reality Model Production

As part of the 2025 structural inspection of the shiploader, SIE captured high-definition imagery of the entire machine’s structural components and used photogrammetry to generate a highly detailed 3D reality model. This model accurately represented the physical condition and geometry of the structure at the time of inspection.

The reality model served as a valuable tool for documenting the current state of the asset, supporting condition assessments, and enhancing the clarity of inspection reporting. It also provided a permanent digital record for future reference, enabling comparison over time and supporting informed asset management decisions.

Why Structural Integrity Engineering Is the Right Choice

Specialist structural engineering advice trusted for over 25 years. Our team's total cumulative knowledge and experience delivers expert guidance on critical, complex, and challenging structural projects across Australia and overseas. We take on projects other companies shy away from.

Providing Trusted Specialised Engineering Services for over 25 Years

Rapid incident recovery support you can rely on. Unexpected incidents can be stressful and costly. Our team responds quickly to help restore operations safely and efficiently, ensuring remedial works can be carried out in a risk-controlled manner.

Responding Fast to Keep Your Assets Operational

Our proven experience and technical expertise supports preventative maintenance, life extension, and asset longevity. Talk to us about how our technical abilities and specialist services can help with your asset reliability.

Reliability You Can Count On From Maintenance to Longevity

Get in touch

Let us know how we can help you.